Dry goods sharing, let me introduce you to the winding machine in one minute!

Dec 19,2022

Wrapping machines (wrapping packaging machines) are widely used in the packaging of products for export, food and beverages, plastics and chemicals, glass and ceramics, and electromechanical castings, reducing packaging costs and preventing damage during transport. They provide dustproof, moisture-proof, and clean packaging. A wrapping machine uses a rotating turntable to rotate cylindrical goods, suitable for the sealed packaging of various cylindrical goods. Applications include the paper, curtain cloth, and non-woven fabric industries, improving logistics efficiency, reducing transport losses, and offering good dust and moisture isolation. There are many series of wrapping machines, which are introduced below.

1. w-series cylindrical radial wrapping machine: This uses two power rollers on a turntable to rotate cylindrical goods and then wraps the radial cylindrical surface. Suitable for spiral wrapping of the circular surface of rolled objects, used in the paper, curtain cloth, and non-woven fabric industries. It improves logistics efficiency, reduces transport losses, and offers dustproof, moisture-proof, and cost-saving advantages.

2. s-series - Horizontal wrapping machine: This uses a rotating arm system to move goods horizontally at a constant speed, used in the plastics, aluminum, sheet metal, pipe, and dyed fabric industries.

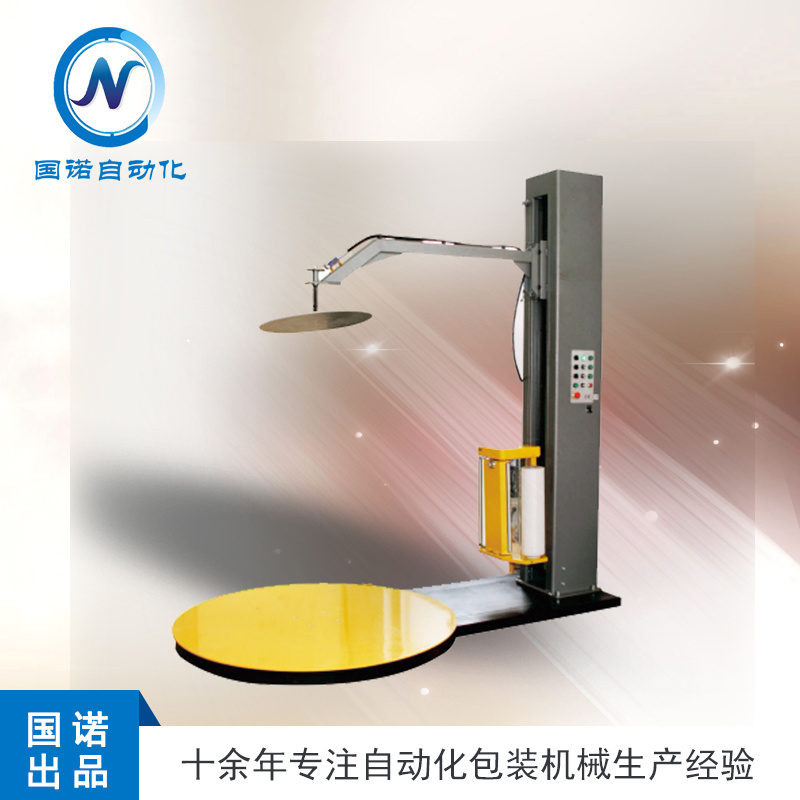

3. NT-series - Trackless wrapping machine: This uses a rotating turntable to rotate goods and then wraps and packages them. Suitable for packaging single or multiple small items, used in the clothing, electrical appliance, and chemical fiber industries. It improves packaging efficiency, reduces transport losses, and offers dustproof, moisture-proof, and cost-saving advantages.

What are the structural characteristics of a wrapping machine? This is introduced below.

1. This winding machine has a stable operating structure, high stability, long life, and a low failure rate digital electronic control circuit.

2. Slow start and stop of the equipment prevents the upper filler from falling off. The touch screen makes operation simple, and the upper and lower packaging layers can be set via data input.

Wrapping machines, also known as winding machines, are designed to meet the packaging requirements of containerized storage, transportation, and mechanized handling of goods. Series of products include pallet-type winding machines, top-pressure tension winding machines, and pre-tension automatic film winding machines, widely used in export, food and beverage, irrigation, papermaking, dyeing, plastics and chemicals, glass and ceramics, and electromechanical castings, reducing packaging costs.

The working principle of a winding machine is to place the object to be wrapped in the center of the turntable. Starting the turntable motor rotates the turntable, causing the object to rotate. Simultaneously, the lifting motor starts, moving the entire winding and bundling machine assembly up and down, wrapping the object in the height direction to achieve overall wrapping. This not only meets the packaging requirements for storage, transportation, and mechanized handling of goods but also prevents damage during transport, providing dustproof, moisture-proof, and clean packaging, reducing production costs, and improving efficiency. During the winding process, the film tension is mainly adjusted, and the film is threaded. Generally, the film tension can be adjusted by adjusting the turntable speed and motor speed. If the turntable speed is greater than the motor speed, the film will be tighter; conversely, it will be looser. This principle is not difficult to operate.

Previous: Introduction to the future prospects of winding machines, come and collect it!

Next: Introduction to winding machines, come and collect it!

Other News

Jan 16,2023

What are the advantages of a winding machine?

The application range of winding machines is very wide. Before using them, we must know the advantages of winding machines so that we can better apply them. If you are interested in this topic, let's take a look together. Hopefully, it can help some relevant people.

Jan 06,2023

How to maintain a winding machine?

With the continuous advancement of science and technology, all walks of life have also developed greatly. The development prospect of winding machines is also very good, so the demand is increasing, and there are more and more manufacturers on the market. As a manufacturer, it is also very necessary for us to tell you about the maintenance methods of winding machines. Interested partners can take a look.

Dec 27,2022

Introduction to the future prospects of winding machines, come and collect it!

What was the development status of wrapping machines in 2022? At present, the development of advanced packaging machinery in the world has shown a trend of integration of machinery, electricity, gas, liquid, light, magnetism, and life. Energy-saving and recyclable products, high-tech and practical products, and intelligent products have become a trend, and this should also be the mainstream development direction of China's packaging machinery industry. In terms of structural adjustment of wrapping machines, it is necessary to change the situation of low technological content as soon as possible, learn from advanced foreign technologies, develop and produce low-consumption large-scale complete sets of equipment and high-tech products, develop suitable wrapping machines according to national conditions, accelerate the updating and upgrading of packaging machinery, and further expand domestic and foreign markets.