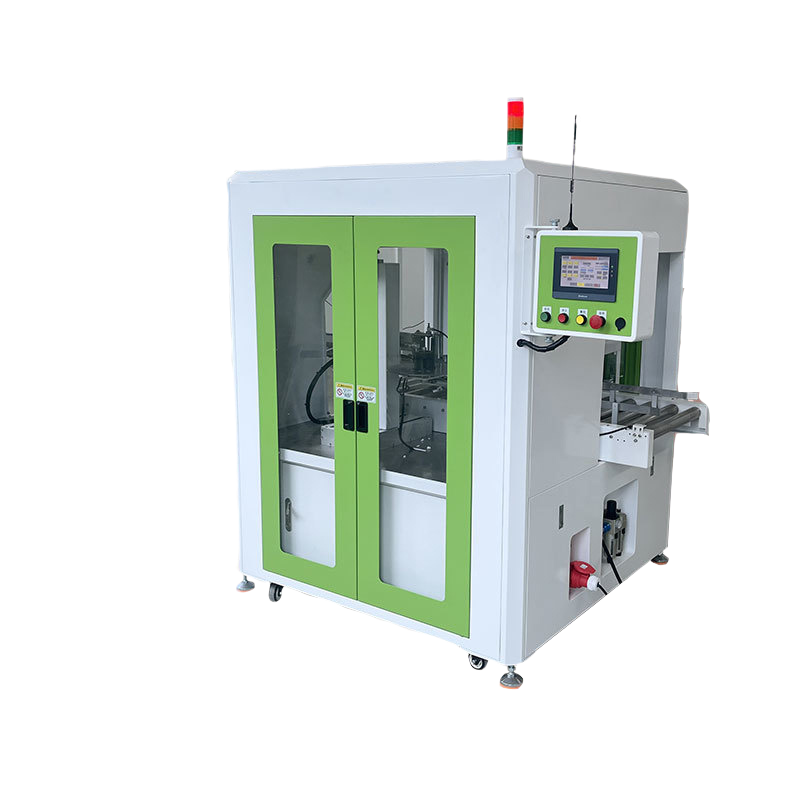

Robot automatic labeling machine

Automatic labeling machine is a device that can stick rolled paper or metal foil labels onto specified packaging containers or products. The back of the label comes with adhesive and is arranged in a regular pattern on a smooth base paper. The peeling mechanism on the labeling machine can automatically peel it off. Labeling can complete various operations such as flat pasting, single-sided or multi-faceted pasting of packaging materials, cylindrical pasting, partial or full coverage cylindrical pasting, concave and corner pasting, etc.

Category:

Keyword:

Description

Automatic labeling machine is a device that can stick rolled paper or metal foil labels onto specified packaging containers or products. The back of the label comes with adhesive and is arranged in a regular pattern on a smooth base paper. The peeling mechanism on the labeling machine can automatically peel it off. Labeling can complete various operations such as flat pasting, single-sided or multi-faceted pasting of packaging materials, cylindrical pasting, partial or full coverage cylindrical pasting, concave and corner pasting, etc.

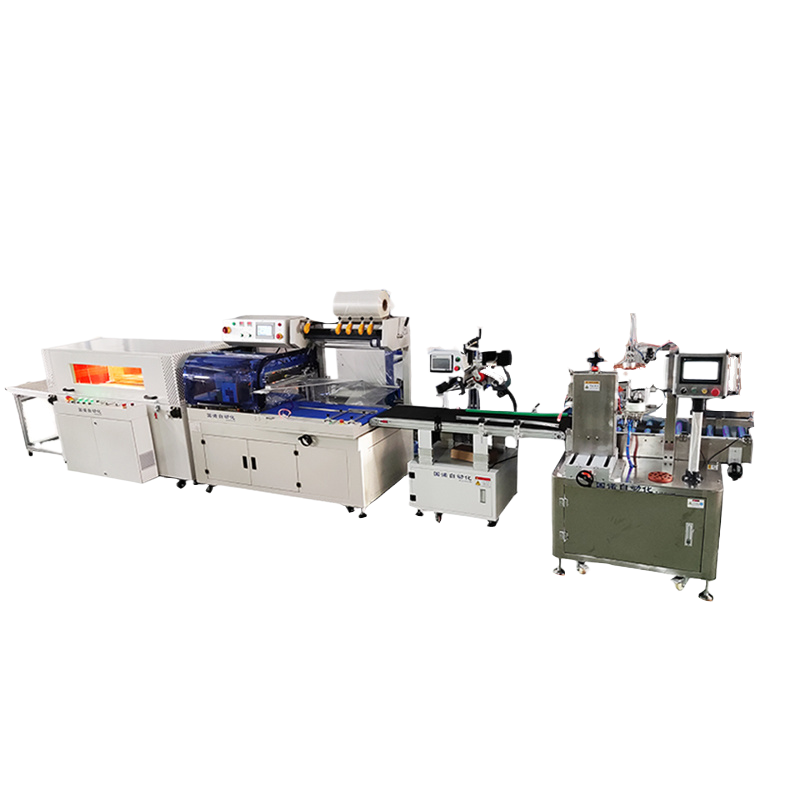

There are many types of automatic labeling machines with different functions, but their basic principles are similar. Automatic labeling machine is a device that uses adhesive to stick paper or metal foil labels onto specified packaging containers. The automatic labeling machine can complete various operations such as flat pasting, single-sided or multi-faceted pasting of packaging materials, cylindrical pasting, partial or full coverage cylindrical pasting, concave and corner pasting, etc.

Features of automatic labeling machine:

A、 Wide applicability: It can not only achieve single label/corner marking on the side (flat) of square/flat bottles (full bottle state), but also achieve single/double label covering function for circumferential positioning of round bottles

B、 Unique material sorting mechanism ensures reliable and effective material sorting when used in conjunction with the production line

C、 The unique corner labeling mechanism ensures that the corner labels on the three sides of the square bottle are flat and wrinkle free

D、 Can be used independently or in conjunction with production lines

Composition of automatic labeling machine:

(1) Unwinding wheel. For passive wheels, used to place drum labels. Usually equipped with adjustable friction braking devices, the purpose is to control the speed and tension of the drum, and maintain smooth paper feeding.

(2) Buffer wheel. The work is connected to the spring. Can swing back and forth. The purpose is to absorb the tension of the roll material when the device is started, maintain the material in contact with each roller, and prevent material breakage.

(3) Guide roller. Composed of two parts, it plays a guiding and positioning role for the roll material.

(4) Drive roller. Composed of a set of active friction wheels. Usually one is a rubber roller and the other is a metal roller, with the backing paper passing between them. The function is to drive the roll material and achieve normal labeling.

(5) Roll up wheel. The driving wheel with friction transmission device is used to rewire and label the base paper. The rotation of the paper delivery wheel does not interfere with the processing of paper by the driving wheel, and the synchronous transmission is adjusted by a friction device.

(6) Peel off the board. There is an angle (usually less than 30 °) at one end of the release board, which is used to make it easier for the label to be printed and detached from the bottom paper when the direction of the bottom paper changes after passing through the release board, achieving contact with the labeled object.

(7) Labeling roller. Apply the label that has detached from the backing paper evenly and smoothly onto the item to be affixed.

Related Products

Advantage

Having a self built factory of 20000 square meters, its three major brands, Xinqi, Qianrun, and Duoweilong, are well-known brands in the industry.

Rated as a specialized and innovative new enterprise in Guangdong Province, possessing multiple world patents and a strong research and development system.

Acquired Duoweilong, invested 30 million yuan, and joined forces to create a new one-stop label printing equipment service concept for customers.

Our products are sold well in more than 30 provinces, municipalities and autonomous regions in China, and exported to multiple countries and regions such as Europe, America, the Middle East, and Southeast Asia.

Product Consultation

If you have found your desired products or want to design your exclusive products, please feel free to contact, we are here for you 24/7.