Remote-controlled winding machine

The winding machine (winding packaging machine) is widely used in the container cost of products such as foreign trade exports, food and beverage, plastic and chemical industries, glass ceramics, and electromechanical castings. It can prevent damage to goods during transportation and play a role in dust prevention, moisture prevention, and cleaning.

Category:

Keyword:

Description

The winding machine (winding packaging machine) is widely used in the container cost of products such as foreign trade exports, food and beverage, plastic and chemical industries, glass ceramics, and electromechanical castings. It can prevent damage to goods during transportation and play a role in dust prevention, moisture prevention, and cleaning.

Seven series of winding machines:

1. T Series - Tray Winding Machine:

It refers to a device that uses a turntable to rotate and drive the pallet cargo to rotate, thereby achieving the winding and wrapping of the cargo. Suitable for packaging goods shipped on pallets (such as container transportation for bulk goods and packaging for loose pallets), widely used in industries such as glass products, hardware tools, electronic appliances, papermaking, ceramics, chemicals, food, beverages, building materials, etc. It can improve logistics efficiency and reduce losses during the shipping process. It has the advantages of dust prevention, moisture resistance, and reduced packaging costs.

2. R Series - Cantilever Winding Machine:

It refers to a device that uses a rotatable cantilever to rotate around goods, thereby achieving wrapping and wrapping of the goods. All goods that can be packaged in the T series can be wrapped using the R series equipment. In addition, its rotating packaging method around the goods is more suitable for wrapping lighter, higher, and unstable products or overweight goods after stacking. The installation method of the machine is flexible, it can be placed on the wall or fixed with a bracket; And it can be connected to the conveyor line as needed to meet the needs of assembly line operations.

3. H series - Loop winding machine:

It refers to a device that wraps and wraps the ring part of circular goods through a film (belt) feeding device that runs around a circular track. Applied to industries such as tires, bearings, steel strips, copper strips, cables, etc. It can improve packaging efficiency and has advantages such as dust prevention, moisture resistance, and reduced packaging costs.

4. Y Series - Cylindrical Axial Winding Machine:

It refers to the sealing packaging of various cylindrical goods that is driven by the rotation of the turntable to rotate as a whole, and is suitable for industries such as papermaking, curtain fabric, non-woven fabric, etc. It can improve logistics efficiency, reduce losses during shipping, and has good dust and moisture insulation properties.

5. W Series - Cylindrical Radial Winding Machine:

It refers to a packaging equipment that uses two power rollers on the turntable to drive the drum shaped cargo to rotate, thereby achieving the wrapping and wrapping of the radial cylindrical surface. Suitable for spiral wrapping of circular surfaces of roll shaped objects, applied in industries such as papermaking, curtain fabrics, non-woven fabrics, etc. It can improve logistics efficiency, reduce losses during shipping, have advantages such as dust and moisture prevention, and lower packaging costs.

6. S Series - Horizontal Winding Machine:

It refers to the rotational motion of goods moving horizontally at a constant speed through a revolving arm system. Applied to industries such as plastic profiles, aluminum materials, sheets, pipes, and dyed fabrics.

7. NT series - Tray free winding machine:

It refers to a device that uses a turntable to rotate and drive the rotation of goods, thereby achieving the wrapping and wrapping of goods. Suitable for packaging single or multiple small-sized goods. Applied to industries such as clothing, electrical appliances, and chemical fibers. It can improve packaging efficiency, reduce losses during shipping, and has advantages such as dust prevention, moisture resistance, and reduced packaging costs.

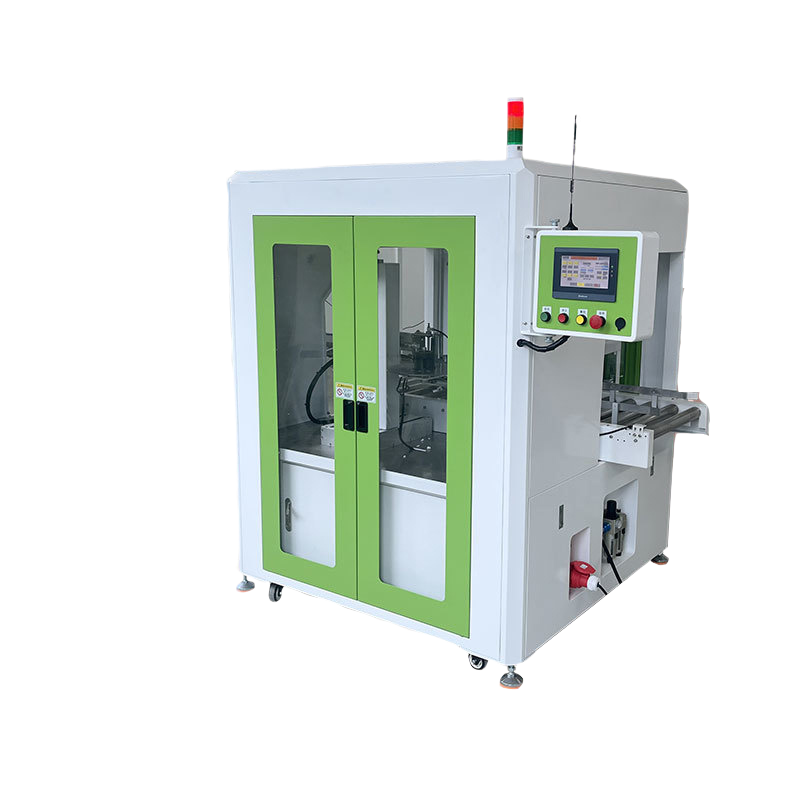

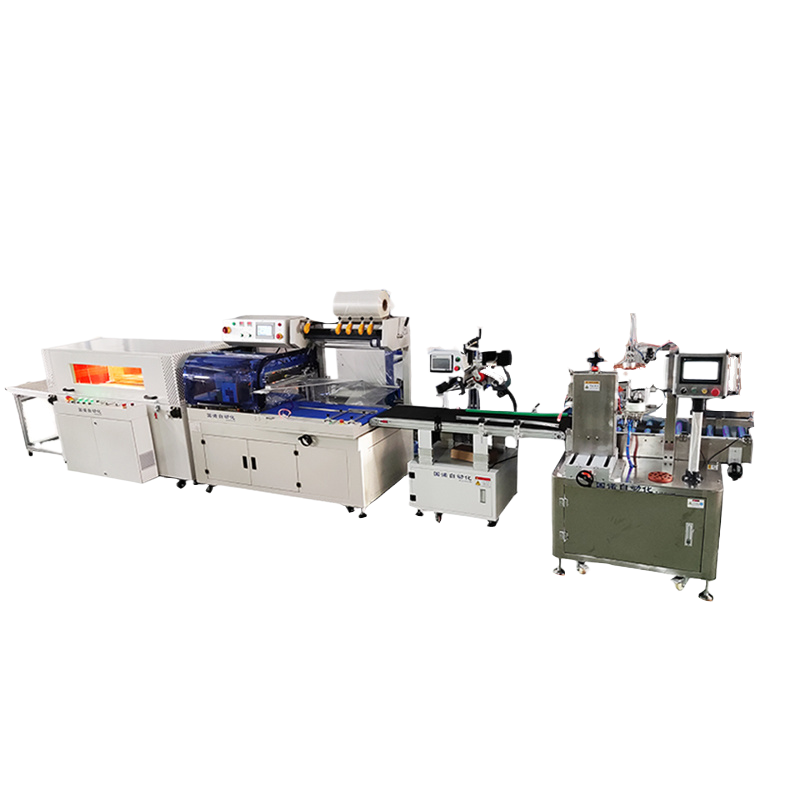

Related Products

Advantage

Having a self built factory of 20000 square meters, its three major brands, Xinqi, Qianrun, and Duoweilong, are well-known brands in the industry.

Rated as a specialized and innovative new enterprise in Guangdong Province, possessing multiple world patents and a strong research and development system.

Acquired Duoweilong, invested 30 million yuan, and joined forces to create a new one-stop label printing equipment service concept for customers.

Our products are sold well in more than 30 provinces, municipalities and autonomous regions in China, and exported to multiple countries and regions such as Europe, America, the Middle East, and Southeast Asia.

Product Consultation

If you have found your desired products or want to design your exclusive products, please feel free to contact, we are here for you 24/7.