How much more efficient are high-speed, fully automatic box folding machines compared to manual box folding?

Apr 18,2022

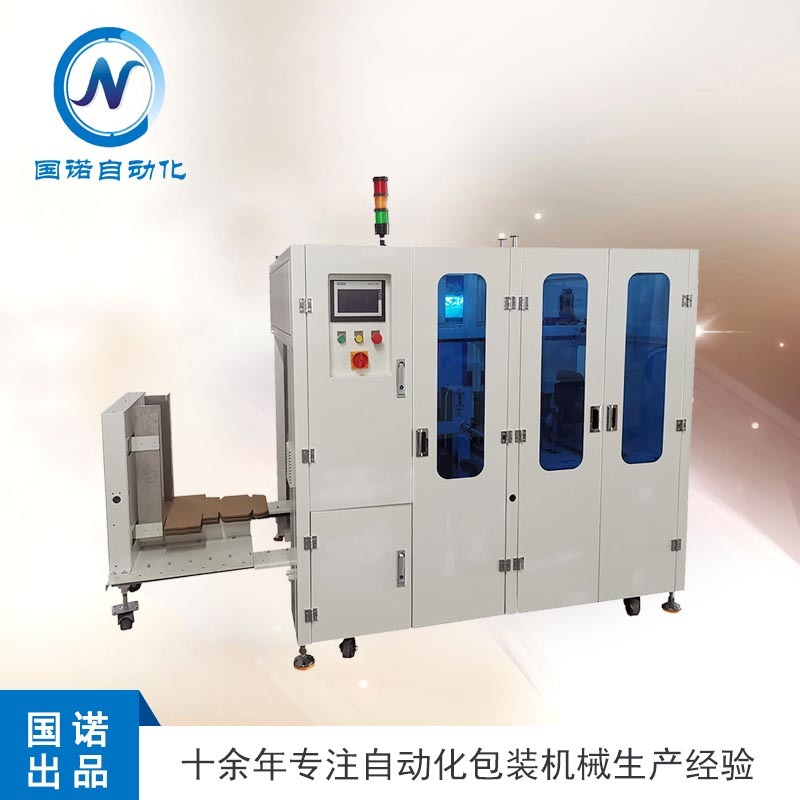

The purpose of a high-speed, fully automatic folding machine is to replace manual labor. Therefore, before purchasing, businesses must know how much manual labor a high-speed, fully automatic folding machine can replace and its efficiency.

Generally, a high-speed, fully automatic folding machine operates at a speed of 25-30 boxes per minute, with an efficiency exceeding 3 times that of manual labor, replacing 3-5 people. It is easy to operate and maintain.

High-speed, fully automatic folding machines are more efficient than ordinary paper box forming machines, but they also have higher requirements for the same paper box; only a few types of paper boxes can be used with high-speed paper box forming machines.

Note: In addition to high-speed, fully automatic folding machines, other packaging machines also use power and air sources. They cannot be used when the power is off.

The outstanding features of high-speed, fully automatic folding machines.

Online shopping has recently become very popular. With the improvement of netizens' living standards, the packaging industry's demand for cartons is increasing, and the requirements for the quality of paper box packaging are also becoming increasingly stringent. Commonly used corrugated cardboard on the market has creasing lines, and the folding lines on the folding cardboard are folded into paper boxes. When the top and bottom boxes need to be assembled for packaging, the bottom box cardboard has two more folds than the top box cardboard. Using a fully automatic folding machine improves the sturdiness of the bottom box, reduces impact, and prevents damage to goods during transportation. However, ordinary folding machines can only fold one specification of paper box, and adding folded cardboard may require a different folding machine, necessitating a new purchase and customization, increasing production costs and reducing competitiveness.

High-speed, fully automatic folding machines are also commonly used in the packaging process. Especially with increasing emphasis on environmental protection and hygiene, the sealing of paper boxes has also become a concern. While paper box lids can be sealed with small folding machines, the seal isn't very tight, and many products cannot achieve the desired packaging effect. Therefore, another packaging process—heat-shrinkable film wrapping—is often necessary to achieve a sealed effect. While this works, many companies find this packaging wasteful and adds to the packaging process.

Fully automatic folding machines use pneumatic actuators and adjustable molds to automatically fold cardboard, automatically locking the cardboard. The equipment is easy to operate, adjust, and is stable. It is widely used in the electricity, toy, food, express delivery, clothing, and auto parts industries. The machine produces aesthetically pleasing paper boxes, saves labor, achieves automated production, is fast and stable, has low noise, and a long service life.

Several important considerations when customizing high-speed, fully automatic folding machine equipment.

1. All specifications of your paper boxes must be communicated to the manufacturer to ensure that all possible box specifications can be used with the folding machine.

2. The configuration of the folding machine (PLC, inverter, air cylinder, etc.) can be customized according to your needs, and the price can also be controlled accordingly.

3. Clearly define the performance and characteristics of the folding machine, and communicate your requirements with the manufacturer.

4. Be sure to choose a reputable and capable folding machine manufacturer for customization.

Previous: How to choose a good automatic winding machine? Let's take a look!

Other News

Dec 08,2025

Unlocking Efficiency: The Benefits of Direct Push Transparent Film Packaging Machines

In the realm of packaging machinery, the Direct Push Transparent Film Packaging Machine stands out as a pioneering solution for manufacturers seeking efficiency and effectiveness in their packaging processes. This type of machine utilizes a direct push mechanism, which directly applies transparent film around products without the need for secondary processes. This innovative approach not only stre

Dec 07,2025

Maximizing Safety and Quality with L-Type Heat Shrink Packaging Machines

Maximizing Safety and Quality with L-Type Heat Shrink Packaging Machines Table of Contents 1. Introduction to L-Type Heat Shrink Packaging Machines 2. Understanding the Functionality of L-Type Heat Shrink Machines 3. Key Benefits of Using L-Type Heat Shrink Packaging Machines 3.1 Enhanced Product Protection 3.2 Improved Operational Efficiency 3.3 Cost-Effectiveness in Packaging 4. Safety Features

Dec 06,2025

Understanding Heat Shrink Packaging Machines: A Comprehensive Guide for Professionals

Heat shrink packaging machines have become a vital component in the manufacturing and packaging industries. These machines utilize heat to shrink a plastic film tightly around products, ensuring they are secure and protected during storage and transportation. Understanding the functionality, advantages, and applications of heat shrink packaging machines can significantly enhance operational effici

Dec 05,2025

The Future of Packaging: Innovations in Open Box Sealing Machine Technology

The Future of Packaging: Innovations in Open Box Sealing Machine Technology Table of Contents Introduction to Open Box Sealing Machines The Evolution of Packaging Technology The Importance of Open Box Sealing Machines in Manufacturing Innovations in Open Box Sealing Technology Sustainability in Packaging Solutions Future Trends in Open Box Sealing Machines Real-World A