Dry goods sharing, let me introduce you to the winding machine in one minute!

Dec 19,2022

Wrapping machines (wrapping packaging machines) are widely used in the packaging of products for export, food and beverages, plastics and chemicals, glass and ceramics, and electromechanical castings, reducing packaging costs and preventing damage during transport. They provide dustproof, moisture-proof, and clean packaging. A wrapping machine uses a rotating turntable to rotate cylindrical goods, suitable for the sealed packaging of various cylindrical goods. Applications include the paper, curtain cloth, and non-woven fabric industries, improving logistics efficiency, reducing transport losses, and offering good dust and moisture isolation. There are many series of wrapping machines, which are introduced below.

1. w-series cylindrical radial wrapping machine: This uses two power rollers on a turntable to rotate cylindrical goods and then wraps the radial cylindrical surface. Suitable for spiral wrapping of the circular surface of rolled objects, used in the paper, curtain cloth, and non-woven fabric industries. It improves logistics efficiency, reduces transport losses, and offers dustproof, moisture-proof, and cost-saving advantages.

2. s-series - Horizontal wrapping machine: This uses a rotating arm system to move goods horizontally at a constant speed, used in the plastics, aluminum, sheet metal, pipe, and dyed fabric industries.

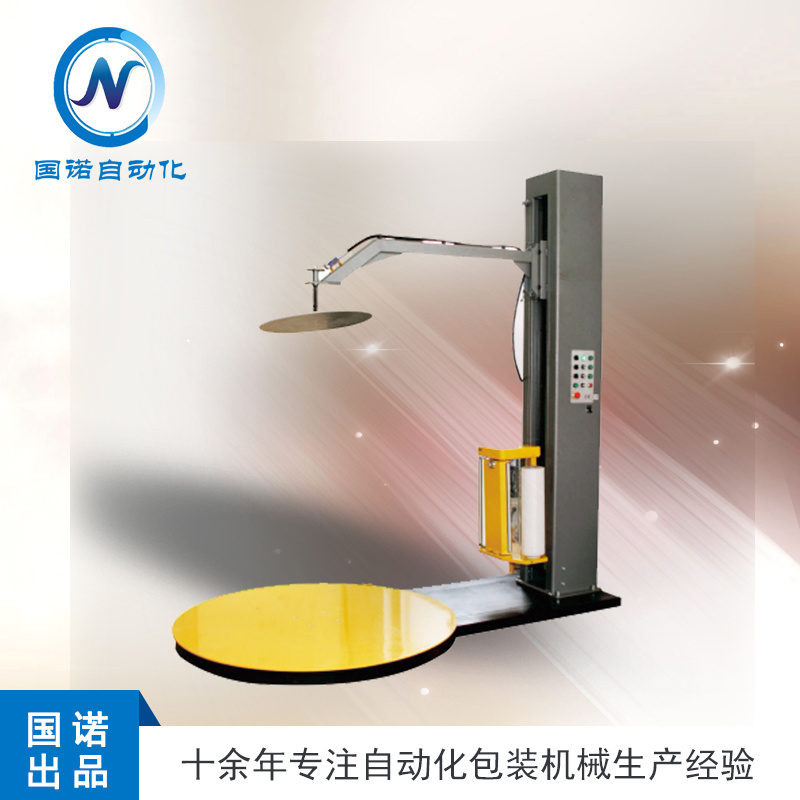

3. NT-series - Trackless wrapping machine: This uses a rotating turntable to rotate goods and then wraps and packages them. Suitable for packaging single or multiple small items, used in the clothing, electrical appliance, and chemical fiber industries. It improves packaging efficiency, reduces transport losses, and offers dustproof, moisture-proof, and cost-saving advantages.

What are the structural characteristics of a wrapping machine? This is introduced below.

1. This winding machine has a stable operating structure, high stability, long life, and a low failure rate digital electronic control circuit.

2. Slow start and stop of the equipment prevents the upper filler from falling off. The touch screen makes operation simple, and the upper and lower packaging layers can be set via data input.

Wrapping machines, also known as winding machines, are designed to meet the packaging requirements of containerized storage, transportation, and mechanized handling of goods. Series of products include pallet-type winding machines, top-pressure tension winding machines, and pre-tension automatic film winding machines, widely used in export, food and beverage, irrigation, papermaking, dyeing, plastics and chemicals, glass and ceramics, and electromechanical castings, reducing packaging costs.

The working principle of a winding machine is to place the object to be wrapped in the center of the turntable. Starting the turntable motor rotates the turntable, causing the object to rotate. Simultaneously, the lifting motor starts, moving the entire winding and bundling machine assembly up and down, wrapping the object in the height direction to achieve overall wrapping. This not only meets the packaging requirements for storage, transportation, and mechanized handling of goods but also prevents damage during transport, providing dustproof, moisture-proof, and clean packaging, reducing production costs, and improving efficiency. During the winding process, the film tension is mainly adjusted, and the film is threaded. Generally, the film tension can be adjusted by adjusting the turntable speed and motor speed. If the turntable speed is greater than the motor speed, the film will be tighter; conversely, it will be looser. This principle is not difficult to operate.

Previous: Introduction to the future prospects of winding machines, come and collect it!

Next: Introduction to winding machines, come and collect it!

Other News

Dec 07,2025

Maximizing Safety and Quality with L-Type Heat Shrink Packaging Machines

Maximizing Safety and Quality with L-Type Heat Shrink Packaging Machines Table of Contents 1. Introduction to L-Type Heat Shrink Packaging Machines 2. Understanding the Functionality of L-Type Heat Shrink Machines 3. Key Benefits of Using L-Type Heat Shrink Packaging Machines 3.1 Enhanced Product Protection 3.2 Improved Operational Efficiency 3.3 Cost-Effectiveness in Packaging 4. Safety Features

Dec 06,2025

Understanding Heat Shrink Packaging Machines: A Comprehensive Guide for Professionals

Heat shrink packaging machines have become a vital component in the manufacturing and packaging industries. These machines utilize heat to shrink a plastic film tightly around products, ensuring they are secure and protected during storage and transportation. Understanding the functionality, advantages, and applications of heat shrink packaging machines can significantly enhance operational effici

Dec 05,2025

The Future of Packaging: Innovations in Open Box Sealing Machine Technology

The Future of Packaging: Innovations in Open Box Sealing Machine Technology Table of Contents Introduction to Open Box Sealing Machines The Evolution of Packaging Technology The Importance of Open Box Sealing Machines in Manufacturing Innovations in Open Box Sealing Technology Sustainability in Packaging Solutions Future Trends in Open Box Sealing Machines Real-World A

Dec 04,2025

Maximizing Efficiency with E-commerce Packaging Machines: A Comprehensive Guide

In the rapidly evolving world of e-commerce, the importance of efficient packaging cannot be overstated. E-commerce packaging machines play a pivotal role in ensuring that products are packaged effectively and delivered to customers in pristine condition. These machines are designed to automate the packaging process, significantly increasing productivity, reducing labor costs, and minimizing human